Warum nicht einfach ausrangierte Batterien aus Elektrofahrzeugen in stationären Systemen verbauen?

2020 war es endlich soweit. In Deutschland und Europa gewinnt die Elektromobilität an Fahrt. Letztes Jahr stiegen die Verkaufszahlen von elektrischen Fahrzeugen trotz der Corona-Pandemie hierzulande um 207 %. Das Verkehrsministerium will bis 2030 zehn Millionen E-Autos auf deutschen Straßen sehen.

Die Anforderungen an Fahrzeugbatterien sind hoch und oft können die Batteriezellen nach mehreren hunderttausend zurückgelegten Kilometern die gewünschte Leistung nicht mehr erbringen – und das obwohl sie noch bis zu 80 % der ursprünglichen Kapazität in sich tragen. Diese Kapazität ist viel zu schade um sie einfach wegzuwerfen.

Eine Autobatterie nach Ende ihres Lebens wegzuschmeißen ist in etwa so wie das Glas Nutella in den Müll zu werfen, nachdem man gerade mal drei Brote damit geschmiert hat.

Die Anforderungen im stationären Bereich sind wesentlich geringer als im Fahrzeug. Warum also nicht einfach die ausrangierten Batterien aus Elektrofahrzeugen nehmen und sie in stationären Systemen verbauen?

In diesem Blog Post geben wir fünf Gründe, weshalb das Konzept Second-Life (noch) nicht serienreif ist und erklären abschließend wie STABL Energy die Verwendung gebrauchter Fahrzeugbatterien wirtschaftlich sinnvoll macht.

Batterien sind wie Menschen

Was erstmal esoterisch klingt, hat einen Funken Wahrheit inne. Die obige Aussage stammt von Ken Boyce, einem Batterieexperten der Zertifizierungsfirma Underwriters Laboratories. Welchen Erfahrungen und Erlebnissen wir während unseres Lebens ausgesetzt sind beeinflusst unseren Gesundheitszustand – und genau so ist es mit Batterien. Nicht erst seit dem Diesel-Skandal von VW weiß man, dass sich die Fahrweisen in der Realität von denem am Prüfstand unterscheiden. Jede Fahrzeugbatterie wird unterschiedlich belastet und hat einen unterschiedlichen Gesundheitszustand. Auch innerhalb der Fahrzeugbatterie können die Gesundheitszustände und Belastbarkeit der einzelnen Module variieren, was es schwierig macht, einen Speicher aus einheitlichen gebrauchten Fahrzeugbatterien aufzubauen.

Der Aufbau von Hochvolt-Batteriespeichersystemen

Der traditionelle Aufbau von Batteriespeichersystemen ist ein weiteres Hindernis, das die Industrialisierung von Second-Life-Speichern erschwert. Es gibt zwei Ansätze, die Systeme aufzubauen: der Hochvolt-Ansatz und der Niedervolt-Ansatz. Beide haben ihre eigenen Vor- und Nachteile:

Der Hochvolt-Ansatz

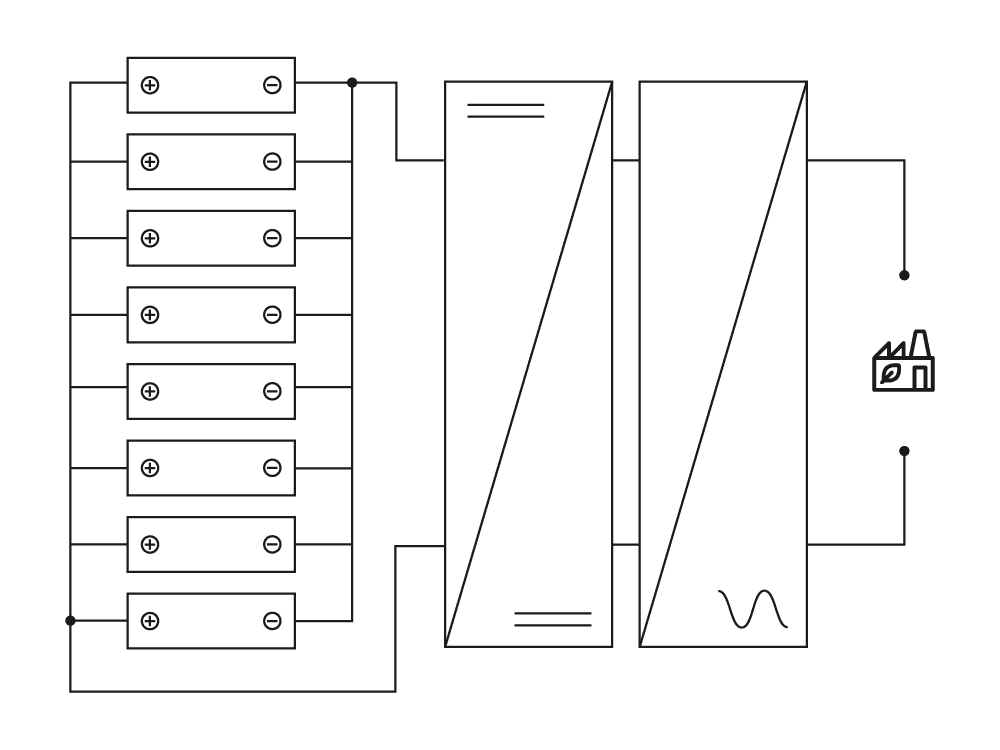

Der klassische Hochvolt-Aufbau eines Batteriespeichers ist wie folgt: Mehrere Batteriepacks oder Module werden fest miteinander verbunden, sodass eine hohe Spannung von bis zu 1200 Volt anliegt. Dieser Hochvoltspeicher wird dann mit dem Plus und Minus-Pol an einen sog. Wechselrichter geschaltet. Dieser wandelt die Gleichspannung des Speichers in die Wechselspannung, die das Netz benötigt und umgekehrt. Vorteil dieses Ansatzes ist sein einfacher Aufbau und die hohe Effizienz: durch die hohe Spannung kann weniger Strom fließen, sodass Verluste reduziert werden. Für Second-Life speziell bringt der Ansatz aber auch einen entscheidenden Nachteil mit sich:

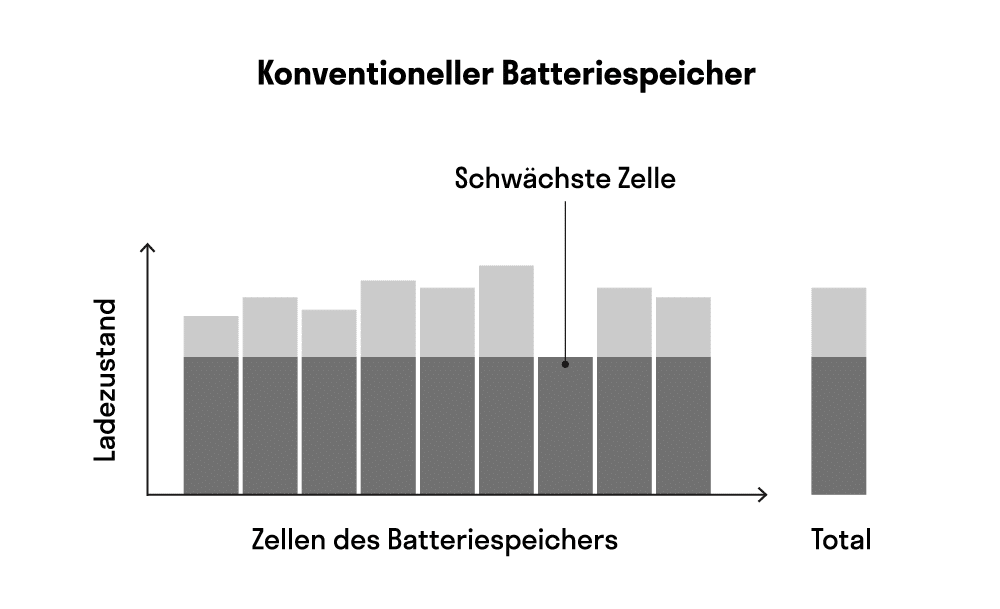

Das schwächste Glied bestimmt die entnehmbare Kapazität

Diese statische Kette aus Batteriespeichern hat, wie jede Kette, die Eigenschaft, dass das schwächste Glied die Performance bestimmt. Konkret: der Speicher mit dem niedrigsten Energieinhalt bestimmt die entnehmbare Kapazität. Bei herkömmlichen neuen Batterien ist das kein so großes Problem, da die Unterschiede in den entnehmbaren Energieinhalten marginal sind. Bei gebrauchten Fahrzeugbatterien sieht das anders aus. Um dem entgegenzuwirken, müssen Batterien einen Prozess durchlaufen, den man Matching nennt.

Der Niedervolt-Ansatz

Um Installation und Wartung von Batteriespeichersystemen zu vereinfachen, gibt es auch den Ansatz, die einzelnen Module parallel zu verschalten, um so die Spannung der Module anzugleichen. Für die Verbindung zum Wechselrichter muss noch ein DC/DC-Wandler zwischengeschaltet werden, da die Spannung der Module geringer ist als die nötige Eingangsspannung des Wechselrichters. Der DC/DC-Wandler verursacht allerdings zusätzliche Kosten im System und wirkt sich dadurch negativ auf die Wirtschaftlichkeit aus. Außerdem entstehen zusätzliche Verluste die sich im Betrieb negativ auf die Kosten auswirken.

Als Zwischenfazit kann man festhalten, dass die beiden populären Ansätze Batteriespeichersysteme aufzubauen ihre Tücken haben, wenn es um den Aufbau von Second-Life-Speichern geht.

Die Wiederaufbereitung ist aufwendig

Um gebrauchte Fahrzeugbatterien in stationären Batteriespeichersystemen einsetzen zu können, sind viele Arbeitsschritte notwendig, die Zeit und Geld kosten. Konkret müssen die Batterie-Packs aus dem Auto entnommen werden, die Zellen müssen getestet, bewertet und gematched werden, damit sie ähnliche Zustände aufweisen. Das Gehäuse muss neu gebaut werden und schließlich müssen die Batterien mit einem Wechselrichter und einem Batteriemanagementsystem und Energiemanagementsystem integriert werden.

Dieser Prozess erfordert sehr viel Handarbeit und ist noch nicht automatisiert, was die Kosten in die Höhe treibt. Das National Renewable Energy Laboratory in den USA geht davon aus, dass die manuelle Arbeit ein Drittel der Kosten für die Wiederaufbereitung von gebrauchten Fahrzeugbatterien ausmacht.

Eine Studie der Boston Consulting Group aus dem Jahr 2020 kommt zu dem Schluss, dass Second-Life auf Grund der hohen Wiederaufbearbeitungskosten kein Business-Case ist.

Man hat keinen Zugriff auf die Batterien

Neben den ökonomischen Herausforderungen, gibt es auch praktische Herausforderungen. Hierbei dreht sich alles um die Frage “Wie kommen wir überhaupt an die alten Fahrzeugbatterien?”. Hans Eric Melin, Managing Director von Circular Energy Storage Research and Consulting widmet sich exklusiv dem Recycling und Second-Life-Markt für Fahrzeugbatterien. Seine Firma hat herausgefunden, dass die Batterie bisher gar nicht aus dem Fahrzeug entnommen wird auch wenn sie theoretisch ihr Lebensende erreicht hat.

Die Energiespeicherbranche sieht bei Elektrofahrzeugen oft nur die Batterie; der Kunde, der das Elektrofahrzeug fährt, sieht allerdings das gesamte Fahrzeug. Und was macht man mit Fahrzeugen, die man nicht mehr fahren möchte? Man verkauft sie auf dem Gebrauchtwagenmarkt. So kommt es derzeit kaum dazu, dass die Batterien aus den alten Elektrofahrzeugen entnommen werden, weil der Kunde keinen Anreiz hat, die Batterie dem Hersteller zurückzugeben. Die Fahrzeuge verlassen die Märkte auf denen sie gekauft wurden und werden in Länder wie Ukraine, Jordanien, Sri Lanka und Neuseeland verkauft.

Um heute an Second-Life-Batterien zu kommen, muss man eher auf Flottenbetreiber schauen als auf den privaten PKW-Markt. Denn Flottenbetreiber, wie Stadtwerke oder Mietwagenfirmen, können kontrollieren, was mit der Batterie im Fahrzeug passiert, wenn sie den Anforderungen nicht mehr genügt. Daher überrascht es nicht, dass viele Second-Life-Projekte auch von Busherstellern und Stadtwerken initiiert werden wie z.B. das Second-Life Projekt von MAN und den Stadtwerken Hamburg.

Der regulatorische Rahmen fehlt

Um sowohl das Beschaffen gebrauchter Fahrzeugbatterien als auch ihr Wiederaufbereiten zu vereinfachen, muss der regulatorische Rahmen angepasst werden. Eine der größten Herausforderungen beim Wiederaufbereiten gebrauchter Fahrzeugbatterien ist, dass die Informationen aus dem Batteriemanagementsystem für Dritte nicht zugänglich sind. Das macht es für Recycling- und Repurposing-Firmen aufwendige, die Batterien zu bewerten und effizient wiederaufzubereiten.

Des Weiteren gibt es keinen Anreiz dafür, dass die Produzenten der Batteriespeicher die Batterien am Ende ihres Lebens wieder einsammeln. Doch das wird sich in Zukunft ändern: am 10. Dezember 2020 hat die Europäische Kommission eine Modernisierung der EU-Rechtsvorschriften für Batterien vorgeschlagen. Dort heißt es unter anderem, dass Batterien aus Elektrofahrzeugen ohne Ausnahme gesammelt werden müssen. Außerdem wird ein Rahmen festgelegt, der die Umnutzung von solchen Batterien in beispielsweise stationären Systemen erleichtern soll.

Ob der Vorschlag angenommen und in der aktuellen Form umgesetzt wird, bleibt abzuwarten. Doch jetzt gibt es schon Expertenstimmen, denen der Vorschlag nicht genügt.

Fazit

Es gibt also noch einige Stolpersteine bis gebrauchte Fahrzeugbatterien wirtschaftlich sinnvoll in stationären Systemen wie Heimspeichern oder Gewerbespeichern eingesetzt werden können. Die größten Herausforderungen sind die aufwendige Wiederaufbereitung der Batterien aber auch das Sourcing, also woher die Batterien kommen, bleibt eine wichtige Frage. Damit das Konzept Second-Life erfolgreich wird, müssen Technologie und Regulatorik weitere Schritte nach vorne machen.

Wir bei STABL Energy tragen dazu bei, dass Second-Life wirtschaftlicher wird. Durch unseren modulare Wechselrichtertechnologie können wir Batteriemodule unterschiedlicher Gesundheitszustände und sogar unterschiedlicher Hersteller zu Speichersystemen kombinieren. Dabei bietet der STABL Wechselrichter höchste Effizienz und garantiert so niedrige Betriebskosten. Durch die Verwendung von Second-Life-Modulen spart der Kunde außerdem bis zu 40 % Investitionskosten.

Möchten Sie mehr über die Wechselrichter-Technologie von STABL Energy erfahren? Laden Sie unser White Paper herunter oder vereinbaren Sie ein persönliches Gespräch mit einem unserer Experten. Wir beraten Sie gerne.

Referenzen und mehr Informationen

https://www.nrel.gov/transportation/battery-second-use-analysis.html

https://www.bcg.com/de-de/publications/2020/case-for-circular-economy-in-electric-vehicle-batteries

https://www.mobilityhouse.com/de_de/magazin/unternehmen/second-life-speicherprojekte.html

https://ec.europa.eu/commission/presscorner/detail/de/ip_20_2312

Sie haben Interesse an einem STABL Speicher?

Nehmen Sie Kontakt mit uns auf. Wir freuen uns darauf, von Ihnen zu hören und Ihre Fragen zu beantworten.